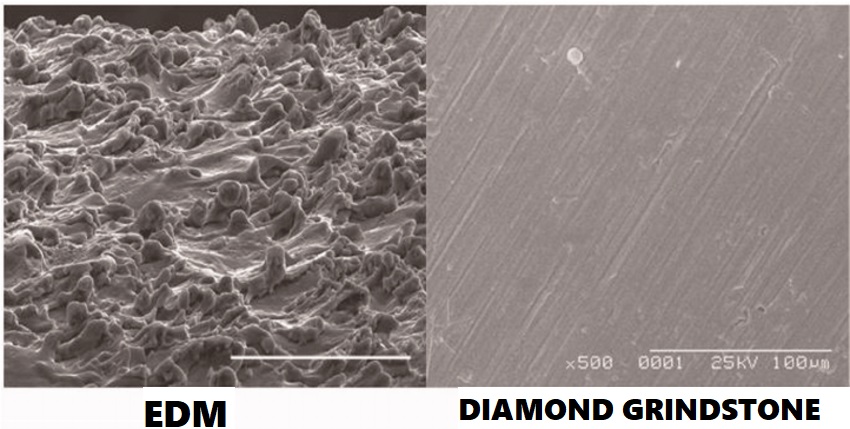

Simple: DOUBLE TOOL LIFE. At least. Yes, we are talking about machining cutting tools. Their carbide insert’s cutting edges can be finished by grinding, with a special diamond grindstone wheel, so to obtain a smooth and compact surface, or they can be finished with EDM, which leaves an irregular surface, full of porosity. They look the same. They are hugely different! The consistency of the quality of the machining is far, far better in case of the grindstone, in other words the desired roughness of the surface can be kept for a bigger number of pieces. Are you sure you are saving money by purchasing EDM finished tools?? Guess what? UMR is manufacturing only diamond grinded carbide tools. Want to further increase the tool life and precision? We manufacture also Policristalline Diamond tools.